Categories

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

select

- Label

- application

- Wood

- Plastic

- Metal

- Aluminium

- Steel

- INOX

- Grass

- Wood with Nails

- Fibre

- Cement

- Concrete

- Bricks

- Polystyrene

- Insulation

- Frozen Materials

- Hardwood

- Laminates

- Ceramic

- Tiles

- Glass

- Fibre Cement Boards

- Nails

- Screw

- Grout

- Plaster

- Glue

- Paint

- Caulk

- Sealants

- Cardboard

- Polyfoam

- Wallpaper

- Mirror

- Paint

- Method

- Chase

- Slice

- Cut

- Plunge

- Trim

- Grind

- Rasp

- Scrape

- Sand

- Drilling

- Polish

- Screw

- Hammer

- Compatible Brand

- Fein

- Makita

- Bosch

- Dewalt

- AEG

- Hitachi

- Metabo

- Skil

- Milwaukee

- Festool

- Fitments

- Plunge Saws

- Mitre Saws

- Cordless Saws

- Circular Saw

- Table Saws

- Reciprocating Saw

- Jig Saw

- Oscillating Saw

- Angle Grinder

- Router

- Impact Drill

- Power Drill

- Hammer drill

- Sander

- Industry

- Home improvement

- Woodworking

- Demolition

- Masonry working

- Storage

- Home Renovation & D.I.Y

- Woodworking & Carpentry

- Concrete & Constructions

- Automobile Maintance

- Electricians, Plumbes & Others

- Shipbuilding & Maintainance

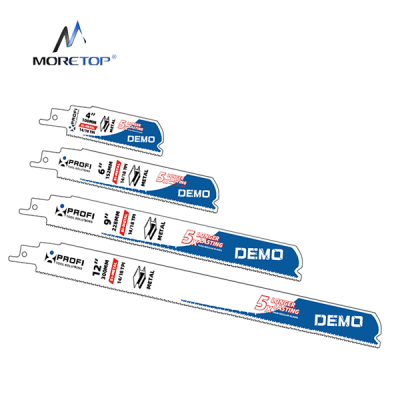

METAL CUTTING BLADES

4 products found

ViewShowcase

Moretop metal cutting reciprocating saw blade have longer life, providing customers with a more cost-effective choice.

Reciprocating saw blades with Full Contact Arched Design are designed for maximum performance in metal cutting applications.

Carbide tooth blades have longer life, providing customers with a more cost-effective choice.

Carbide tooth blades have longer life, providing customers with a more cost-effective choice

Metal Cutting Blades Maintenance and Care:

Regular Cleaning: Clean the blades after each use to remove metal shavings and debris, ensuring optimal cutting performance.

Lubrication: Apply cutting lubricants or coolants during metal cutting to minimize heat build-up and extend the blade's lifespan.

Blade Inspection: Regularly inspect the blades for signs of wear, such as dullness, missing teeth, or blade warping. Replace worn-out or damaged blades to maintain cutting quality and safety.

Proper Storage: Store the blades in a dry and clean environment to prevent corrosion. Keep them in a protective case or cover when not in use.

Metal Cutting Blades Safety Tips:

Wear Personal Protective Equipment (PPE): Always wear safety goggles, gloves, ear protection, and appropriate clothing when operating metal cutting blades to protect yourself from potential hazards.

Secure Workpiece: Secure the metal workpiece firmly using clamps or vises to prevent movement or vibrations during cutting, ensuring accurate and safe cuts.

Use Cutting Fluids: Apply cutting fluids or lubricants specifically designed for metal cutting to minimize heat, reduce friction, and enhance cutting performance.

Avoid Overheating: Take breaks during prolonged metal cutting to prevent overheating of the blade, which can lead to premature wear or damage.

Keep Blades Away from Children and Pets: Store metal cutting blades in a safe and secure location out of the reach of children and pets.

Metal Cutting Techniques:

Adjust the cutting speed and feed rate based on the type and thickness of the metal being cut to achieve optimal cutting results.

Use appropriate blade tooth count and configuration for different metal cutting applications, considering the material thickness and desired cutting quality.

Securely clamp the metal workpiece and ensure proper alignment before cutting to ensure accurate and clean cuts.

Excellent quality, original package design and our social responsibility allows MORETOP to stay unique and hold its position in the global market. Besides, we provide our partners with exceptional marketing solutions for their competitiveness. Welcome to contact and develop together with us.MORE

Contact us

For support or any questions:

Email us at info@moretoptools.com

call us: 86-571-82650982-8001

Wechat: profitool