Categories

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

select

- Label

- application

- Wood

- Plastic

- Metal

- Aluminium

- Steel

- INOX

- Grass

- Wood with Nails

- Fibre

- Cement

- Concrete

- Bricks

- Polystyrene

- Insulation

- Frozen Materials

- Hardwood

- Laminates

- Ceramic

- Tiles

- Glass

- Fibre Cement Boards

- Nails

- Screw

- Grout

- Plaster

- Glue

- Paint

- Caulk

- Sealants

- Cardboard

- Polyfoam

- Wallpaper

- Mirror

- Paint

- Method

- Chase

- Slice

- Cut

- Plunge

- Trim

- Grind

- Rasp

- Scrape

- Sand

- Drilling

- Polish

- Screw

- Hammer

- Compatible Brand

- Fein

- Makita

- Bosch

- Dewalt

- AEG

- Hitachi

- Metabo

- Skil

- Milwaukee

- Festool

- Fitments

- Plunge Saws

- Mitre Saws

- Cordless Saws

- Circular Saw

- Table Saws

- Reciprocating Saw

- Jig Saw

- Oscillating Saw

- Angle Grinder

- Router

- Impact Drill

- Power Drill

- Hammer drill

- Sander

- Industry

- Home improvement

- Woodworking

- Demolition

- Masonry working

- Storage

- Home Renovation & D.I.Y

- Woodworking & Carpentry

- Concrete & Constructions

- Automobile Maintance

- Electricians, Plumbes & Others

- Shipbuilding & Maintainance

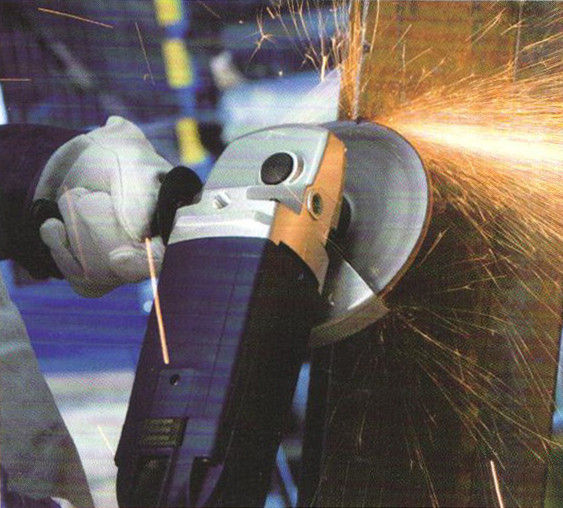

ABRASIVE DISCS

·Bonded Discs are all in compliance with MPA standard to ensure extra safety and long life.

·Please follow MORETOP Disc color code when you choose among metal, stone or INOX abrasive disc according to the material being cut or grinded.

·Ensure that the correct wheel is properly mounted.

4 products found

ViewShowcase

All cutting abrasive discs comply with international standards and safety requirements such as EN 12413.

All cutting abrasive discs comply with international standards and safety requirements such as EN 12413.

All cutting abrasive disc comply with international standards and safety requirements such as EN 12413.

All Abrasive wheels comply with international standards and safety requirements such as EN 12413.

Overview of Abrasive Discs

Abrasive discs, also known as grinding discs or sanding discs, are indispensable tools used in various industries and applications for grinding, sanding, and finishing tasks. These discs are designed to remove material, smooth surfaces, and achieve desired levels of precision and surface quality. With their versatility and effectiveness, abrasive discs are widely used in metalworking, woodworking, automotive, and construction industries.

Types and Features of Abrasive Discs

Abrasive discs come in different types, each designed for specific grinding and finishing applications. Here are some common types and their features:

Flap Discs: Flap discs consist of overlapping abrasive flaps mounted on a backing plate. They are versatile and suitable for both grinding and finishing tasks. Flap discs provide aggressive material removal and produce smooth finishes on various surfaces.

Grinding Wheels: Grinding wheels are circular discs with bonded abrasive grains. They are used for heavy-duty grinding applications, such as removing welds, shaping metal, and sharpening tools. Grinding wheels are available in various abrasive materials and grit sizes for different metalworking requirements.

Sanding Discs: Sanding discs feature a flat circular shape with abrasive particles adhered to a backing material. They are used for sanding and smoothing surfaces, removing paint or rust, and preparing materials for finishing. Sanding discs are available in different grit sizes for coarse to fine sanding applications.

Cutting Discs: Cutting discs, also known as cutoff wheels, are thin abrasive discs used for cutting through metal, masonry, or other materials. They are ideal for precise and efficient cutting operations. Cutting discs are available in various diameters and thicknesses for different cutting needs.

Wire Brushes: Although not strictly discs, wire brushes are often included in the category of abrasive discs. They feature bristles made of wire, which are used for cleaning, deburring, and surface preparation tasks. Wire brushes are available in different configurations, such as cup brushes and wheel brushes.

Applications of Abrasive Discs

Abrasive discs find extensive use in a wide range of applications, including:

Metalworking: Abrasive discs are commonly used in metal fabrication, welding, and machining processes. They help remove excess material, smooth welds, and prepare surfaces for painting or coating.

Woodworking: Abrasive discs are essential for sanding wooden surfaces, shaping edges, and achieving smooth finishes on wood projects. They are used in woodworking shops, furniture manufacturing, and carpentry tasks.

Automotive: In the automotive industry, abrasive discs are used for grinding and finishing tasks on metal surfaces, including bodywork repairs, rust removal, and paint preparation.

Construction: Abrasive discs are employed in construction projects for tasks such as concrete surface preparation, tile cutting, and masonry work.

Maintenance and Safety Considerations

To ensure the longevity and safe use of abrasive discs, consider the following:

Inspect Discs: Before use, inspect the discs for any damage or signs of wear. Discs with cracks, chips, or worn-out abrasive particles should be replaced.

Proper Mounting: Follow the manufacturer's instructions for mounting abrasive discs securely on appropriate power tools. Ensure that the disc is centered and securely tightened.

Safety Gear: Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask, to protect against flying debris and inhalation of dust particles.

Storage: Store abrasive discs in a clean, dry location away from excessive heat, moisture, and direct sunlight. Proper storage helps prevent damage and maintains their effectiveness.

Choosing the Right Abrasive Discs

Consider the following factors when selecting abrasive discs:

Material Compatibility: Ensure that the abrasive disc is suitable for the material you intend to work on. Different materials require different abrasive materials and grit sizes for optimal performance.

Disc Size: Choose the appropriate disc size based on the power tool and the specific application. Using the correct disc size ensures efficient and safe operation.

Application Type: Select the right type of abrasive disc based on the intended application, such as grinding, sanding, cutting, or surface preparation.

Grit Size: Grit size determines the coarseness or fineness of the abrasive particles on the disc. Coarser grits are suitable for material removal, while finer grits are ideal for finishing and smoothing.

With their versatility, durability, and effectiveness, abrasive discs are indispensable tools for grinding and finishing applications across various industries. By understanding their features, applications, and proper usage, you can make informed decisions when selecting and using abrasive discs, ensuring efficient and high-quality results in your projects.

Excellent quality, original package design and our social responsibility allows MORETOP to stay unique and hold its position in the global market. Besides, we provide our partners with exceptional marketing solutions for their competitiveness. Welcome to contact and develop together with us.MORE

Contact us

For support or any questions:

Email us at info@moretoptools.com

call us: 86-571-82650982-8001

Wechat: profitool