Categories

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

select

- Label

- application

- Wood

- Plastic

- Metal

- Aluminium

- Steel

- INOX

- Grass

- Wood with Nails

- Fibre

- Cement

- Concrete

- Bricks

- Polystyrene

- Insulation

- Frozen Materials

- Hardwood

- Laminates

- Ceramic

- Tiles

- Glass

- Fibre Cement Boards

- Nails

- Screw

- Grout

- Plaster

- Glue

- Paint

- Caulk

- Sealants

- Cardboard

- Polyfoam

- Wallpaper

- Mirror

- Paint

- Method

- Chase

- Slice

- Cut

- Plunge

- Trim

- Grind

- Rasp

- Scrape

- Sand

- Drilling

- Polish

- Screw

- Hammer

- Compatible Brand

- Fein

- Makita

- Bosch

- Dewalt

- AEG

- Hitachi

- Metabo

- Skil

- Milwaukee

- Festool

- Fitments

- Plunge Saws

- Mitre Saws

- Cordless Saws

- Circular Saw

- Table Saws

- Reciprocating Saw

- Jig Saw

- Oscillating Saw

- Angle Grinder

- Router

- Impact Drill

- Power Drill

- Hammer drill

- Sander

- Industry

- Home improvement

- Woodworking

- Demolition

- Masonry working

- Storage

- Home Renovation & D.I.Y

- Woodworking & Carpentry

- Concrete & Constructions

- Automobile Maintance

- Electricians, Plumbes & Others

- Shipbuilding & Maintainance

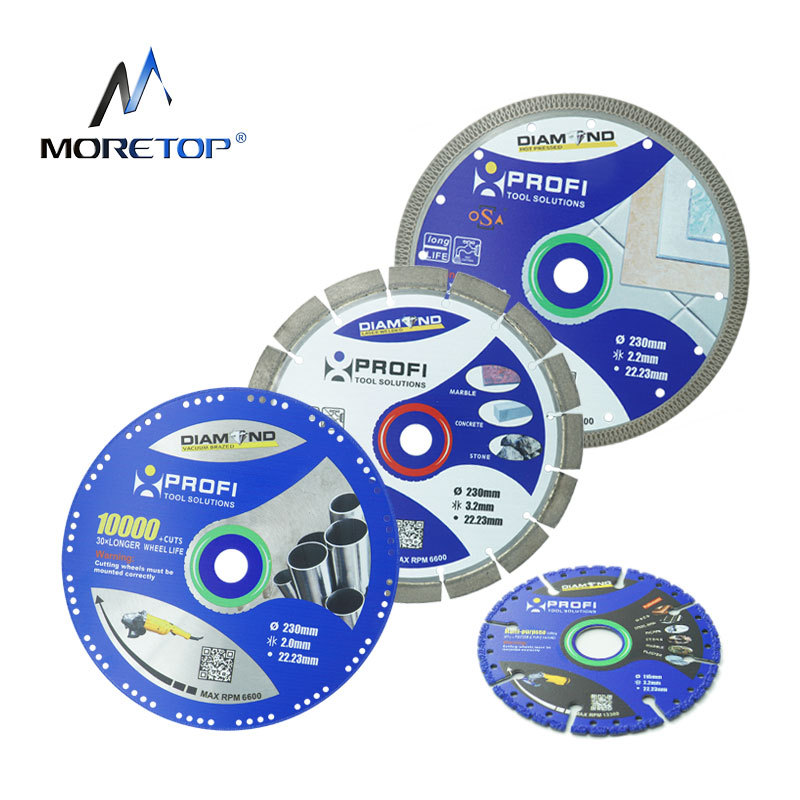

CONCRETE BLADES

Features:

·MORETOP Diamond Blade is produced with high-strength hot pressing technology, which not only improves cutting ability and fineness but also isn't easy to deform at high temperature.

·It has good stability and low vibration printed by UV processing technology and packed in customized package while is good at dry/wet cutting.

3 products found

ViewShowcase

Moretop Super Thin Turbo Diamond Blade is a perfect solution in cutting hard materials such as tile, porcelain and marble.

Moretop Diamond blade is a perfect solution in cutting hard materials such as tile, porcelain and marble.

Moretop Diamond blade is a perfect solution in cutting hard materials.

Concrete Blades: Exceptional Features for Precise Concrete Cutting

Concrete Blades are specifically designed to provide exceptional cutting performance for concrete projects. With their outstanding features, these blades offer unparalleled power, precision, and durability, ensuring precise cutting results in various concrete applications. Key features include:

High Diamond Concentration: These blades feature a high concentration of industrial-grade diamonds embedded in the segment, allowing for efficient cutting through tough concrete materials.

Fast Cutting Speed: Equipped with specially designed segments and advanced bonding agents, Concrete Blades deliver fast and efficient cutting, reducing project time and enhancing productivity.

Smooth and Clean Cuts: The diamond segments on Concrete Blades are precisely engineered to provide clean, chip-free cuts, resulting in smooth and professional-looking finished surfaces.

Long-lasting Performance: Constructed with premium materials and advanced manufacturing techniques, Concrete Blades offer excellent durability and extended blade life, ensuring consistent cutting performance project after project.

Wet or Dry Cutting: Depending on the specific blade design, Concrete Blades can be used for wet or dry cutting, providing versatility for different job site conditions and requirements.

Proper Maintenance and Care for Concrete Blades:

To maximize the lifespan and optimize the performance of your Concrete Blades, proper maintenance and care are crucial. Follow these essential tips to ensure their longevity:

Clean Blades After Use: Thoroughly clean the blades after each use to remove concrete residue, dirt, and debris. Use a brush or compressed air to clean the segments and ensure smooth operation.

Check Blade Condition: Regularly inspect the blade for signs of wear, damage, or diamond segment loss. Replace any blades that show significant wear or damage to maintain optimal cutting performance.

Lubrication: If using water for wet cutting, ensure a constant water flow to the blade during operation to lubricate and cool the blade effectively. For dry cutting, use blade-specific lubricants to reduce friction and heat buildup.

Proper Blade Storage: Store your Concrete Blades in a dry and secure location, preferably in a protective blade case or sleeve, to prevent moisture, dust, and physical damage.

Safety Precautions for Concrete Cutting:

Safety is paramount when working with Concrete Blades. Adhere to these essential precautions to protect yourself and others:

Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, a dust mask, gloves, and hearing protection, to safeguard against potential hazards such as dust, flying debris, and noise.

Secure Work Area: Ensure the work area is properly secured and clear of bystanders. Mark off the cutting zone and use caution tape if necessary to prevent unauthorized access.

Blade Guard and Depth Adjustment: Check that the blade guard is properly installed and functioning correctly. Adjust the blade depth according to the material thickness to minimize blade exposure and enhance safety.

Power Tool Safety: Familiarize yourself with the operation and safety features of the cutting tool. Follow the manufacturer's guidelines for proper tool handling, including starting, stopping, and maintaining control during cutting operations.

Proper Waste Disposal: Dispose of concrete waste and used blades responsibly, following local regulations and guidelines.

Comprehensive Application Guide for Concrete Blades:

Concrete Blades excel in a wide range of concrete cutting applications. Refer to this comprehensive guide to achieve optimal cutting results:

Concrete Slab Cutting: Whether for construction or remodeling projects, Concrete Blades are perfect for cutting through concrete slabs, sidewalks, driveways, and other flat surfaces with precision and efficiency.

Concrete Block and Brick Cutting: Use Concrete Blades to cut through concrete blocks and bricks for various applications, including masonry work, building facades, and landscaping projects.

Concrete Pipe Cutting: With their robust cutting capabilities, Concrete Blades are ideal for cutting through concrete pipes during plumbing and underground utility installations.

Concrete Wall and Floor Cutting: Achieve accurate cuts in concrete walls and floors for creating openings, installing windows, or performing renovations using high-quality Concrete Blades.

Concrete Demolition: When it comes to concrete demolition tasks, Concrete Blades provide the cutting power needed to break through reinforced concrete structures and remove concrete sections effectively.

Selecting the Perfect Concrete Blades:

Selecting the right Concrete Blades is crucial for achieving optimal cutting performance. Keep these factors in mind during the selection process:Blade Diameter: Choose a blade with the appropriate diameter that matches the cutting tool and suits the desired cutting depth and material thickness.

Segment Type: Different segment types, such as segmented, turbo, or continuous rim, offer specific cutting characteristics. Consider the application requirements to determine the most suitable segment type.

Bond Strength: The bond strength of the blade determines its resistance to wear and the ability to retain diamond particles. Select the appropriate bond strength based on the hardness of the concrete material.

Wet or Dry Cutting: Decide whether you require blades suitable for wet cutting or dry cutting, depending on your project needs and job site conditions.

Quality and Brand Reputation: Opt for renowned brands with a reputation for manufacturing high-quality Concrete Blades. Read customer reviews and seek recommendations to ensure reliability and performance.

By following these guidelines and recommendations, you can harness the full potential of Concrete Blades and achieve exceptional cutting results in your concrete projects.

Excellent quality, original package design and our social responsibility allows MORETOP to stay unique and hold its position in the global market. Besides, we provide our partners with exceptional marketing solutions for their competitiveness. Welcome to contact and develop together with us.MORE

Contact us

For support or any questions:

Email us at info@moretoptools.com

call us: 86-571-82650982-8001

Wechat: profitool