Categories

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

select

- Label

- application

- Wood

- Plastic

- Metal

- Aluminium

- Steel

- INOX

- Grass

- Wood with Nails

- Fibre

- Cement

- Concrete

- Bricks

- Polystyrene

- Insulation

- Frozen Materials

- Hardwood

- Laminates

- Ceramic

- Tiles

- Glass

- Fibre Cement Boards

- Nails

- Screw

- Grout

- Plaster

- Glue

- Paint

- Caulk

- Sealants

- Cardboard

- Polyfoam

- Wallpaper

- Mirror

- Paint

- Method

- Chase

- Slice

- Cut

- Plunge

- Trim

- Grind

- Rasp

- Scrape

- Sand

- Drilling

- Polish

- Screw

- Hammer

- Compatible Brand

- Fein

- Makita

- Bosch

- Dewalt

- AEG

- Hitachi

- Metabo

- Skil

- Milwaukee

- Festool

- Fitments

- Plunge Saws

- Mitre Saws

- Cordless Saws

- Circular Saw

- Table Saws

- Reciprocating Saw

- Jig Saw

- Oscillating Saw

- Angle Grinder

- Router

- Impact Drill

- Power Drill

- Hammer drill

- Sander

- Industry

- Home improvement

- Woodworking

- Demolition

- Masonry working

- Storage

- Home Renovation & D.I.Y

- Woodworking & Carpentry

- Concrete & Constructions

- Automobile Maintance

- Electricians, Plumbes & Others

- Shipbuilding & Maintainance

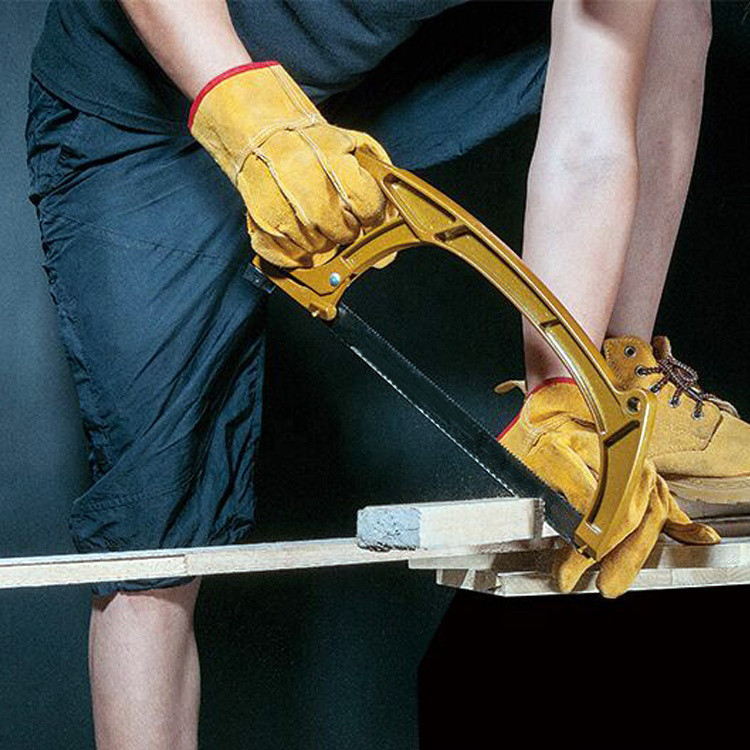

HACKSAW BLADES

Features:

·Bi-metal construction (HSS available) Suitable for pipe, tubing and solids.

·Cuts wood, plastic or any machinable metal including conduit, stainless steel tubing, angle iron, copper tubing, structural materials, etc.

0 products found

ViewShowcase

Overview of Hack Saw Blades:

Hacksaw blades are essential cutting tools that offer versatility, precision, and efficiency. These blades are designed to tackle a wide range of cutting tasks, providing clean and accurate cuts in various materials. With their sharp teeth and durable construction, hacksaw blades are a go-to choice for professionals and DIY enthusiasts.

Maintenance and Care Tips for Hack Saw Blades:

To ensure the longevity and optimal performance of your hacksaw blades, proper maintenance and care are essential. Follow these tips to keep your blades in top condition:

Regular Cleaning: After each use, clean the blades thoroughly with a brush or cloth to remove any debris or particles. This prevents clogging and ensures smooth cutting.

Lubrication: Apply a small amount of cutting oil or lubricant to the blades before cutting. This helps reduce friction and heat, resulting in improved cutting performance and prolonged blade life.

Storage: Store your hacksaw blades in a dry and clean environment to prevent moisture and rust. Consider using a blade case or sheath to protect them from physical damage.

Safety Guidelines for Working with Hack Saw Blades:

Safety should always be a top priority when using hacksaw blades. Follow these guidelines to ensure a safe working environment:

Personal Protective Equipment (PPE): Wear safety goggles, gloves, and appropriate clothing to protect yourself from potential hazards during cutting. Safety glasses prevent eye injuries from flying debris, while gloves provide hand protection.

Secure Workpiece: Use clamps or a vise to secure the workpiece firmly before cutting. This prevents slipping and ensures stability during the cutting process.

Controlled Cutting: Apply consistent and controlled pressure while cutting. Avoid forcing the blade or using excessive force, as it can lead to blade breakage or accidents.

Applications and Versatility of Hack Saw Blades:

Hacksaw blades find extensive applications in various industries and projects. Here are some common applications where hacksaw blades excel:

Metal Cutting: Hacksaw blades are ideal for cutting different types of metals, including steel, aluminum, and copper. They can tackle tasks such as cutting pipes, rods, or metal profiles with precision.

Plastic Cutting: These blades are also effective in cutting various types of plastics, such as PVC, acrylic, or ABS. They provide clean and accurate cuts without causing melting or chipping.

Woodworking: Hacksaw blades can handle woodworking projects, such as cutting wood boards, dowels, or small branches. They offer the flexibility to make both straight cuts and intricate designs.

General Repairs: From household repairs to automotive maintenance, hacksaw blades are versatile tools for cutting bolts, screws, and plastic pipes.

Choosing the Right Hack Saw Blades:

Selecting the appropriate hacksaw blades is crucial for achieving optimal cutting performance. Consider the following factors when choosing your blades:

Teeth Per Inch (TPI): The TPI determines the cutting speed and the type of material the blade can effectively cut. Coarser blades with lower TPI are suitable for softer materials, while blades with higher TPI provide smoother cuts on harder materials.

Blade Length: Choose the blade length based on the thickness of the material you'll be cutting. Longer blades offer extended reach and cutting capacity, while shorter blades provide better maneuverability in tight spaces.

Blade Material: Consider the material composition of the blades. High-quality carbon steel blades are suitable for general-purpose cutting, while bi-metal blades offer enhanced durability and longevity.

Excellent quality, original package design and our social responsibility allows MORETOP to stay unique and hold its position in the global market. Besides, we provide our partners with exceptional marketing solutions for their competitiveness. Welcome to contact and develop together with us.MORE

Contact us

For support or any questions:

Email us at info@moretoptools.com

call us: 86-571-82650982-8001

Wechat: profitool