Categories

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

select

- Label

- application

- Wood

- Plastic

- Metal

- Aluminium

- Steel

- INOX

- Grass

- Wood with Nails

- Fibre

- Cement

- Concrete

- Bricks

- Polystyrene

- Insulation

- Frozen Materials

- Hardwood

- Laminates

- Ceramic

- Tiles

- Glass

- Fibre Cement Boards

- Nails

- Screw

- Grout

- Plaster

- Glue

- Paint

- Caulk

- Sealants

- Cardboard

- Polyfoam

- Wallpaper

- Mirror

- Paint

- Method

- Chase

- Slice

- Cut

- Plunge

- Trim

- Grind

- Rasp

- Scrape

- Sand

- Drilling

- Polish

- Screw

- Hammer

- Compatible Brand

- Fein

- Makita

- Bosch

- Dewalt

- AEG

- Hitachi

- Metabo

- Skil

- Milwaukee

- Festool

- Fitments

- Plunge Saws

- Mitre Saws

- Cordless Saws

- Circular Saw

- Table Saws

- Reciprocating Saw

- Jig Saw

- Oscillating Saw

- Angle Grinder

- Router

- Impact Drill

- Power Drill

- Hammer drill

- Sander

- Industry

- Home improvement

- Woodworking

- Demolition

- Masonry working

- Storage

- Home Renovation & D.I.Y

- Woodworking & Carpentry

- Concrete & Constructions

- Automobile Maintance

- Electricians, Plumbes & Others

- Shipbuilding & Maintainance

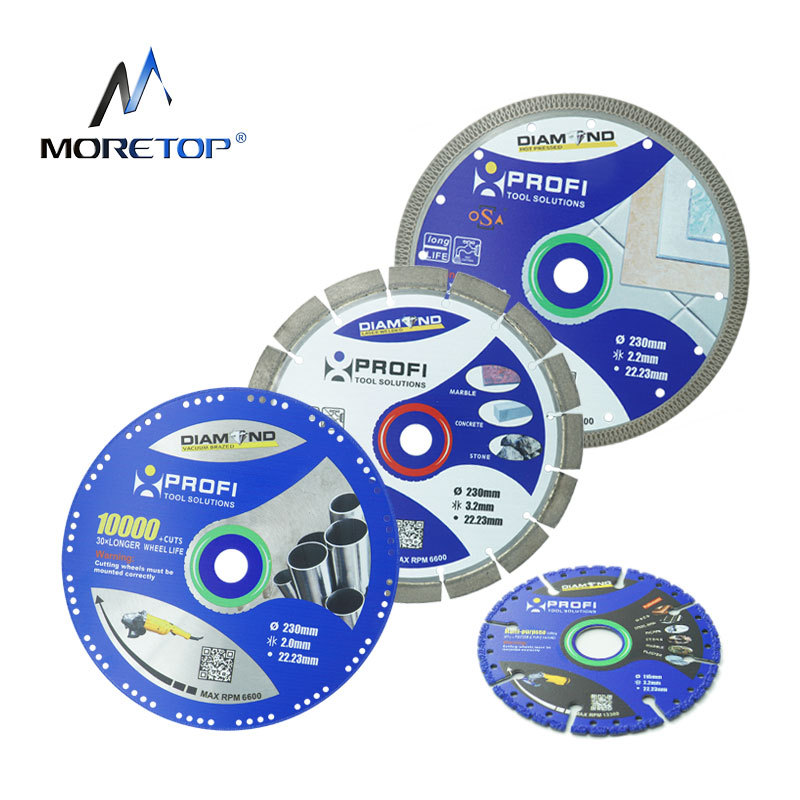

REINFORCED CONCRETE CUTTING BLADES

Features:

·MORETOP Diamond Blade is produced with high-strength hot pressing technology, which not only improves cutting ability and fineness but also isn't easy to deform at high temperature.

·It has good stability and low vibration printed by UV processing technology and packed in customized package while is good at dry/wet cutting.

1 products found

ViewShowcase

Moretop Diamond blade is a perfect solution in cutting hard materials such as tile, porcelain and marble.

Reinforced Concrete Cutting Blades: Unleash the Power of Precision

Reinforced Concrete Cutting Blades are specially designed to tackle the challenges of cutting through reinforced concrete with ease and precision. These blades offer exceptional cutting performance, enabling efficient and accurate cuts in various reinforced concrete applications. Key features include:

High Diamond Concentration: These blades are engineered with a high concentration of diamond particles, providing superior cutting power and durability, allowing for faster and more efficient cutting through reinforced concrete.

Segmented Rim Design: The segmented rim design of Reinforced Concrete Cutting Blades helps dissipate heat generated during cutting, reducing blade wear and ensuring precise and clean cuts.

Reinforced Core: The blades feature a reinforced steel core that enhances stability and reduces vibrations, resulting in smoother and more controlled cutting operations.

Laser-Welded Segments: The segments of these blades are laser-welded for maximum strength and durability, ensuring long-lasting performance in demanding applications.

Compatibility: Reinforced Concrete Cutting Blades are suitable for use with various cutting tools, including circular saws and angle grinders, making them versatile for different job site requirements.

Proper Maintenance and Care for Reinforced Concrete Cutting Blades:

To maximize the lifespan of your Reinforced Concrete Cutting Blades and ensure optimal cutting performance, proper maintenance and care are crucial. Follow these tips:

Clean Blades After Use: After each cutting session, thoroughly clean the blades to remove concrete debris, dust, or any other contaminants. Use a wire brush or compressed air to clean the blade's segments and rim.

Check Blade Condition: Regularly inspect the blade for signs of wear, such as segment loss or damage. Replace worn blades to maintain cutting accuracy and safety.

Lubrication: Depending on the cutting method (wet or dry), use appropriate lubrication. For wet cutting, ensure a continuous water flow to the blade. For dry cutting, use a blade-specific lubricant to reduce friction and heat buildup.

Storage: Store Reinforced Concrete Cutting Blades in a dry and clean environment, preferably in a protective case or sleeve, to prevent moisture and physical damage.

Safety Precautions for Reinforced Concrete Cutting:

Safety should always be a top priority when working with Reinforced Concrete Cutting Blades. Follow these precautions to ensure a safe working environment:

Personal Protective Equipment (PPE): Wear the appropriate PPE, including safety goggles, a dust mask, gloves, and hearing protection, to protect against potential hazards such as flying debris, dust, and noise.

Secure Workpiece: Ensure the reinforced concrete structure or slab is securely supported and clamped to prevent movement or collapse during cutting.

Blade Guard and Depth Adjustment: Ensure the blade guard is properly installed and functional. Adjust the cutting depth according to the concrete thickness to minimize blade exposure and enhance safety.

Proper Handling: Familiarize yourself with the operation and safety features of the cutting tool. Follow the manufacturer's guidelines for proper tool handling, including starting, stopping, and maintaining control during cutting operations.

Waste Disposal: Dispose of concrete waste and used blades responsibly, following local regulations and guidelines.

Comprehensive Application Guide for Reinforced Concrete Cutting Blades:

Reinforced Concrete Cutting Blades excel in a wide range of cutting applications involving reinforced concrete. Refer to this comprehensive guide for efficient cutting solutions:

Slab Cutting: Use Reinforced Concrete Cutting Blades to make precise and straight cuts in reinforced concrete slabs, ensuring clean edges and accurate dimensions.

Pipe and Duct Openings: These blades are ideal for creating openings in reinforced concrete pipes and ducts, allowing for efficient installation or repairs.

Demolition and Renovation: Cut through reinforced concrete structures during demolition or renovation projects, providing controlled and accurate cuts to remove sections or modify existing structures.

Bridge and Road Construction: Reinforced Concrete Cutting Blades are essential tools for bridge and road construction, allowing for efficient cutting of concrete components such as bridge decks, road curbs, and barriers.

Concrete Foundation Work: From foundation walls to footings, Reinforced Concrete Cutting Blades provide precise and reliable cutting solutions for various concrete foundation applications.

Choosing the Right Reinforced Concrete Cutting Blades:

When selecting Reinforced Concrete Cutting Blades, consider the following factors to ensure optimal cutting performance:

Blade Size: Choose the appropriate blade diameter that matches your cutting tool and suits the desired cutting depth and project requirements.

Blade Type: Consider the specific blade type suitable for reinforced concrete cutting, such as segmented blades or turbo blades, depending on the application and cutting conditions.

Wet or Dry Cutting: Evaluate the project requirements and job site conditions to determine whether wet cutting or dry cutting is more suitable.

RPM Compatibility: Ensure the Reinforced Concrete Cutting Blades are compatible with the recommended RPM (Rotations Per Minute) of your cutting tool for safe and efficient operation.

By following these guidelines and using high-quality Reinforced Concrete Cutting Blades, you can achieve exceptional cutting performance and efficiency in your reinforced concrete projects. Always refer to the manufacturer's instructions, recommendations, and safety guidelines for specific blade usage, operating conditions, and any additional considerations.

Excellent quality, original package design and our social responsibility allows MORETOP to stay unique and hold its position in the global market. Besides, we provide our partners with exceptional marketing solutions for their competitiveness. Welcome to contact and develop together with us.MORE

Contact us

For support or any questions:

Email us at info@moretoptools.com

call us: 86-571-82650982-8001

Wechat: profitool