Categories

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

select

- Label

- application

- Wood

- Plastic

- Metal

- Aluminium

- Steel

- INOX

- Grass

- Wood with Nails

- Fibre

- Cement

- Concrete

- Bricks

- Polystyrene

- Insulation

- Frozen Materials

- Hardwood

- Laminates

- Ceramic

- Tiles

- Glass

- Fibre Cement Boards

- Nails

- Screw

- Grout

- Plaster

- Glue

- Paint

- Caulk

- Sealants

- Cardboard

- Polyfoam

- Wallpaper

- Mirror

- Paint

- Method

- Chase

- Slice

- Cut

- Plunge

- Trim

- Grind

- Rasp

- Scrape

- Sand

- Drilling

- Polish

- Screw

- Hammer

- Compatible Brand

- Fein

- Makita

- Bosch

- Dewalt

- AEG

- Hitachi

- Metabo

- Skil

- Milwaukee

- Festool

- Fitments

- Plunge Saws

- Mitre Saws

- Cordless Saws

- Circular Saw

- Table Saws

- Reciprocating Saw

- Jig Saw

- Oscillating Saw

- Angle Grinder

- Router

- Impact Drill

- Power Drill

- Hammer drill

- Sander

- Industry

- Home improvement

- Woodworking

- Demolition

- Masonry working

- Storage

- Home Renovation & D.I.Y

- Woodworking & Carpentry

- Concrete & Constructions

- Automobile Maintance

- Electricians, Plumbes & Others

- Shipbuilding & Maintainance

WIRE BRUSHES

product feature

Features:

·MORETOP Wire brushs are used for cleaning surfaces,removing rust and paint.

11 results

ViewShowcase

Moretop Hand Scratch Brush, With Plastic Handle is made light and heavy cleaning and also in narrow places.

Moretop Crimped Wire Circular Brush are available to fit on portable angle grinders, large angle grinders, etc.

Designed particularly suitable for work on internal corners, using a one-hand and large angle grinder.

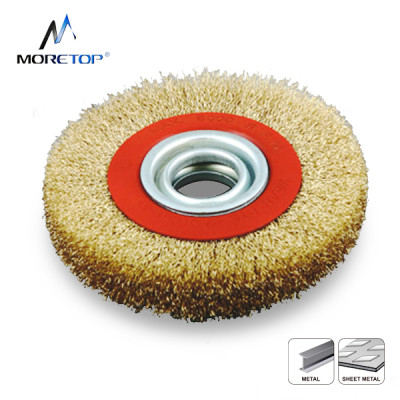

Moretop Crimped Wire Bowl Brushes are ideally suited for use on stationary machines, pneumatic grinders and electric tools.

Moretop Steel Wire Brush is suitable for light-to-medium-duty cleaning applications, such as preparing metal before welding.

Moretop Crimped Wire Brush with high-quality wire construction and 15mm shaft for convenient mounting on hand-held power tools.

Moretop hammer drill bits are designed for fast drilling of correctly sizes holes to ensure optimum anchor performance.

Moretop Wire brushes provide a high-impact brushing action and are suitable for cleaning large surface areas of metal work.

Moretop Wire brushes provide a high-impact brushing action and are suitable for cleaning large surface areas of metal work.

Moretop Wire brushes provide a high-impact brushing action and are suitable for cleaning large surface areas of metal work.

Moretop Wire brushes provide a high-impact brushing action and are suitable for cleaning large surface areas of metal work.

Overview of Wire Brushes

Wire brushes are essential tools used for various cleaning, deburring, and surface preparation tasks. They consist of bristles made of wire, which are attached to a handle or a rotating device. Wire brushes are available in different configurations, wheel brushes, and handheld brushes. These brushes are widely used in industries such as metalworking, woodworking, automotive, and maintenance.

Types and Features of Wire Brushes

Wire brushes come in different types, each designed for specific applications. Here are some common types and their features:

Wheel Brushes: Wheel brushes feature a circular design with wire bristles radially mounted on a wheel-shaped base. They are used for cleaning, deburring, and blending operations on curved or irregular surfaces. Wheel brushes are available in different diameters and bristle materials, offering versatility for various applications.

Handheld Brushes: Handheld wire brushes are compact brushes with a handle for easy gripping. They are commonly used for manual cleaning, rust removal, and surface preparation in hard-to-reach areas or small spaces. Handheld brushes are available in different shapes and sizes, allowing precise control during cleaning tasks.

Applications of Wire Brushes

Wire brushes find wide-ranging applications in different industries and tasks, including:

Metalworking: Wire brushes are commonly used in metalworking processes for cleaning and surface preparation. They help remove rust, paint, scale, and oxidation from metal surfaces, preparing them for welding, painting, or coating.

Woodworking: Wire brushes are used in woodworking projects for cleaning and distressing wood surfaces. They can be used to create textured finishes or remove old paint or finishes from wooden objects or furniture.

Automotive: In the automotive industry, wire brushes are used for cleaning engine parts, removing rust from metal surfaces, and preparing surfaces for painting or refinishing.

Maintenance and Household: Wire brushes are handy tools for general cleaning and maintenance tasks. They can be used for cleaning grills, removing stubborn dirt or debris from surfaces, or preparing surfaces before applying adhesives or sealants.

Maintenance and Safety Considerations

To ensure the safe and effective use of wire brushes, consider the following:

Handle with Care: Handle wire brushes with care, as the bristles can be sharp and may cause injury if mishandled. Always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, to protect yourself from flying bristles or debris.

Regular Inspection: Before use, inspect the wire brush for any damaged or loose bristles. Replace the brush if it shows signs of wear or if bristles are missing or bent.

Proper Technique: Use the wire brush with the appropriate pressure and motion for the task at hand. Avoid excessive force that could damage the workpiece or cause the brush to splinter.

Storage: Store wire brushes in a clean and dry area, away from moisture or corrosive substances. Proper storage helps maintain the integrity of the bristles and extends the brush's lifespan.

Choosing the Right Wire Brush

Consider the following factors when selecting a wire brush:

Bristle Material: Select the appropriate bristle material based on the surface you are cleaning or preparing. Steel bristles are suitable for tough cleaning tasks, while brass or stainless steel bristles are gentler and less likely to scratch sensitive surfaces.

Bristle Stiffness: Choose the right bristle stiffness depending on the application. Softer bristles are suitable for light cleaning or delicate surfaces, while stiffer bristles provide more aggressive cleaning action.

Brush Size and Configuration: Consider the size and configuration of the brush based on the area or surface you will be working on.

Handle Design: For handheld wire brushes, select a handle design that provides a comfortable grip and control during use.

By understanding the types, features, applications, and maintenance considerations of wire brushes, you can effectively use these versatile tools for various cleaning and surface preparation tasks. Choose the right wire brush for your specific needs, and follow proper safety practices to achieve optimal results.

Excellent quality, original package design and our social responsibility allows MORETOP to stay unique and hold its position in the global market. Besides, we provide our partners with exceptional marketing solutions for their competitiveness. Welcome to contact and develop together with us.MORE

Contact us

For support or any questions:

Email us at info@moretoptools.com

call us: 86-571-82650982-8001

Wechat: profitool