10 Factors to Consider when Sharpening a Circular Saw Blade

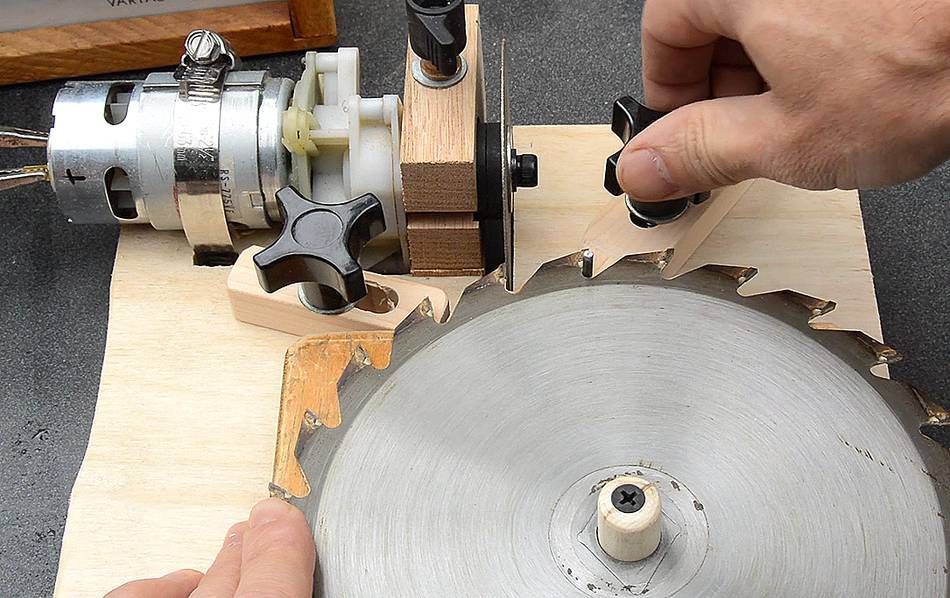

The circular saw blade will become dull after a certain period of use, or even break the teeth. Failure to sharpen in time will affect the service life of the circular saw blade, reduce the cutting quality and destroy the performance of the circular saw. Then when sharpening the circular saw blade, we can consider the following factors.

1. Large deformation of the substrate, inconsistent thickness, large tolerance of the inner hole

When there is a problem with the above-mentioned congenital defects of the substrate, no matter what type of equipment is used, there will be sharpening errors. The large deformation of the substrate will cause deviations on the two side angles, and the inconsistent thickness of the substrate will cause deviations on both the relief angle and the rake angle. If the accumulated tolerance is too large, the quality and accuracy of the saw blade will be seriously affected.

2. Gear sharpening mechanism

The quality of the gear sharpening of alloy circular saw blades depends on the model structure and assembly. At present, there are about two types of models in the market:

One is the German floating ink type. This type adopts vertical sharpening pin, all advantages adopt hydraulic stepless motion, all feed system adopts V-shaped guide rail and ball screw to work, accurate positioning of tooth extraction, firm positioning center of the saw blade, and high precision of sharpening.

The second type is the current horizontal type. The sliding precision of the mechanical transmission gear and the mechanical gap is poor, the smooth performance of the clamping piece is low, the adjustment of the center of the support piece is difficult, and the gear extraction mechanism or reliability is poor.

The two sides of the plane and the left and right rear corners are not ground at the same center, the angle is difficult to control, and the mechanical wear is large, which makes it difficult to ensure accuracy.

3. Welding factors

The large deviation of the alloy pair during welding affects the sharpening accuracy, resulting in a large pressure on the sharpening head while a small pressure on the other, and the clearance angle also has the above-mentioned effect. Poor welding angles and unavoidable factors have an unavoidable influence on sharpening.

4. Sharpening wheel quality and grain size width

When using a sharpening wheel to sharpen alloy sheets, pay attention to the particle size of the sharpening wheel. If the particle size is too coarse, it will cause sharpening wheel marks during sharpening. The diameter of the sharpening wheel and the width and thickness of the sharpening wheel is determined according to the length of the alloy or the different tooth profiles and the conditions of each surface of the alloy. There must be a targeted selection of a suitable sharpening wheel.

5. Feed speed of sharpening head

The sharpening quality of alloy saw blades depends entirely on the feed speed of the sharpening head. Generally, the feed speed of alloy circular saw blades is 0.5 to 6 mm/sec. That is, it should be within 20 teeth per minute, more than 20 teeth per minute. If the feed speed is too high, it will cause the sharpening wheel to produce convex and concave surfaces, which will affect the sharpening accuracy and waste the sharpening wheel.

6. Sharpening center

All saw blade sharpening should be centered on the base, not on the edge of the knife. The surface sharpening center cannot be established, and the machining center for the rear angle and the rake angle cannot sharpen a saw blade.

It is necessary to carefully observe the thickness of the alloy when sharpening the side angles. If the thickness is different, the sharpening center will also change accordingly. Regardless of the thickness of the alloy, the centerline of the sharpening wheel should be kept in a straight line with the welding position when sharpening the surface, otherwise, an angle difference will occur, which will affect the cutting.

7. Clipping mechanism

The clamping mechanism is firm, stable, and reliable. It is the main part of the knife sharpening. The clamping mechanism must not be loosened at all during knife sharpening, otherwise, the gear sharpening will be out of control due to deviation.

8. Sharpening stroke

Regardless of the sharpening of any part of the saw blade, the sharpening stroke of the sharpening head is very important. Generally, the sharpening wheel is required to exceed the workpiece by 1 mm or exit by 1 mm, otherwise, the tooth surface will produce a two-sided blade.

9. Program selection

Knife sharpening is generally set with three different program options of coarse, fine, and sharpening, which need to be selected according to the product requirements. It is recommended to use the fine sharpening program when sharpening the rake angle.

10. Flush the knives

A large amount of tungsten and emery wheel powder are produced during sharpening. If the surface of the tool is not washed and the pores of the sharpening wheel are not washed in time, it will easily cause the sharpening tool to fail to sharpen the smoothness of the circular saw blade.

Moretop Tools produces a full range of circular saw blades, covering wood cutting, metal cutting, aluminum cutting, fireproof cement cutting, etc., and we control the quality of circular saw blades in all aspects to meet the actual needs of users. If you want to know more about circular saw blades after reading the above, please contact us to get it.

As a professional manufacturer of multi-function power tool accessories and equipment, we have accumulated rich design and production experience in this field. We have established a complete quality inspection system, and the products we provide are of excellent quality and can cope with a variety of complex situations. At the same time, we always put customers' needs first and can provide customers with thoughtful one-stop services and effective solutions. If you want to buy our circular saw blade for metals, please contact us immediately!